What are 3D Scanner Volume Measurement?

3D scanner volume measurement refers to the process of using a 3D scanner to accurately measure the volume of an object or space in three-dimensional space. This technology allows for precise and detailed measurements to be taken, providing valuable data for various applications such as industrial design, architecture, archaeology, and more. By capturing the shape and dimensions of an object from multiple angles, a 3D scanner can create a digital model that accurately represents its volume. This information can then be used for analysis, visualization, and comparison purposes. In summary, 3D scanner volume measurement is a powerful tool that enables accurate and efficient measurement of volumes in three-dimensional space.

Why are 3D Scanner Volume Measurement Important?

3D scanner volume measurement is important for a variety of reasons. One key reason is its ability to accurately and efficiently capture the dimensions of objects or spaces in three-dimensional form. This technology is particularly useful in industries such as manufacturing, architecture, and healthcare where precise measurements are crucial for design, analysis, and quality control purposes. By using 3D scanners for volume measurement, businesses can streamline their processes, reduce errors, and improve overall productivity. Additionally, the data collected from 3D scanner volume measurements can be used for creating detailed models, conducting simulations, and making informed decisions, ultimately leading to better outcomes and cost savings.

Technologies Used in 3D Scanner Volume Measurement

Technologies used in 3D scanner volume measurement include laser scanning, structured light scanning, and photogrammetry. Laser scanning involves emitting a laser beam onto the object being scanned and measuring the time it takes for the beam to reflect back, creating a 3D point cloud. Structured light scanning uses patterns of light projected onto the object to create a 3D model based on how the patterns deform. Photogrammetry involves taking multiple photos of an object from different angles and using software to stitch them together into a 3D model. These technologies are essential for accurately measuring the volume of objects in various industries such as manufacturing, construction, and archaeology.

Recent Advancements in 3D Scanner Volume Measurement

Recent advancements in 3D scanner volume measurement have revolutionized various industries by providing more accurate and efficient ways to measure the volume of objects and spaces. These scanners use advanced technology such as laser scanning and photogrammetry to capture detailed 3D images, allowing for precise volume calculations. This technology has been particularly beneficial in fields like architecture, construction, manufacturing, and archaeology, where accurate volume measurements are crucial for planning and analysis. By streamlining the measurement process and reducing human error, 3D scanners have significantly improved productivity and decision-making in these industries. Brief answer: Recent advancements in 3D scanner volume measurement have transformed industries by offering more accurate and efficient ways to measure object and space volumes, benefiting fields like architecture, construction, manufacturing, and archaeology.

Application Areas of 3D Scanner Volume Measurement

The application areas of 3D scanner volume measurement are diverse and wide-ranging. One key area where this technology is utilized is in industrial manufacturing processes, where accurate volume measurements are crucial for quality control and ensuring precise product dimensions. Another important application is in the field of archaeology and cultural heritage preservation, where 3D scanners are used to create detailed digital replicas of artifacts and historical sites. Additionally, 3D scanner volume measurement is also employed in healthcare for creating custom-fitted prosthetics and orthotics, as well as in construction and architecture for precise building measurements and design. Overall, the versatility and accuracy of 3D scanner volume measurement make it a valuable tool across various industries and disciplines. Brief answer: The application areas of 3D scanner volume measurement include industrial manufacturing, archaeology, healthcare, and construction, among others, due to its ability to provide accurate and detailed measurements for a wide range of purposes.

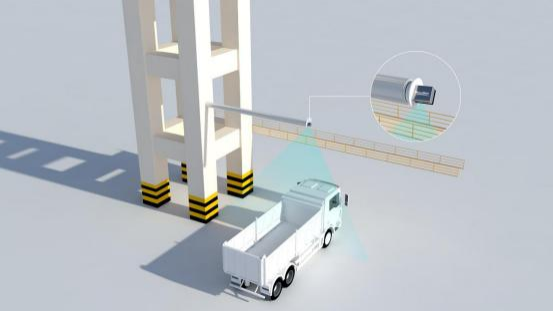

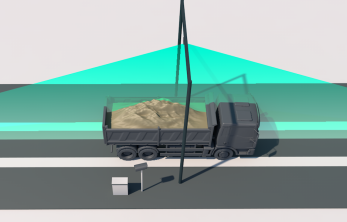

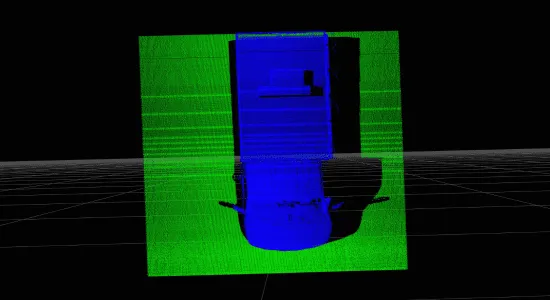

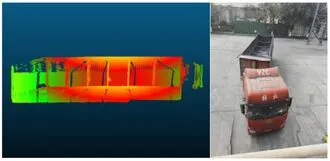

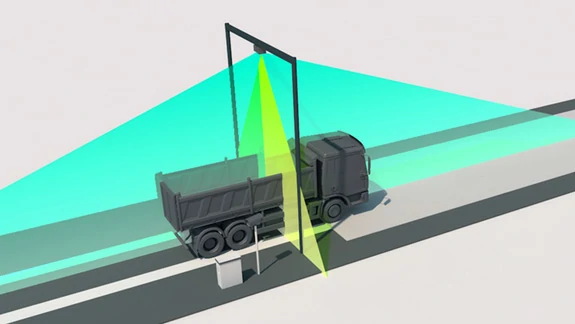

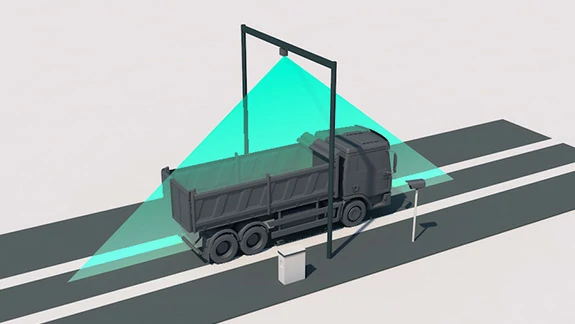

Neuvition Volume Measurement Solution

Neuvition offers a comprehensive volume measurement solution designed to meet the needs of various industries, including truck, warehouse, and outdoor pile measurement. Our solutions leverage advanced technologies to provide accurate, reliable, and cost-effective volume measurement data, enabling businesses to optimize their operations and make data-driven decisions.

Neuvition Single Line LiDAR Solutions

Neuvition's Single Line LiDAR solutions, including the Titan M1 SL, Titan P1, and Titan W1 with PTZ, are designed to provide accurate and efficient volume measurement in various applications. These solutions combine high-resolution laser scanning with advanced software to deliver precise data and user-friendly interfaces, making volume measurement more accessible and effective than ever before.

FAQ

Contact Us

If you have any questions or suggestions, please leave a message, we will get in touch with you within 24 hours!