What is Forklift Collision Avoidance

Forklift collision avoidance is a safety system designed to prevent accidents and collisions involving forklifts in warehouses, factories, and other industrial settings. This technology uses sensors, cameras, and alarms to detect obstacles, pedestrians, or other vehicles in the vicinity of the forklift. By providing real-time alerts and warnings to the operator, collision avoidance systems help reduce the risk of accidents, injuries, and damage to property. Ultimately, the goal of forklift collision avoidance is to improve workplace safety and efficiency by minimizing the potential for collisions and ensuring a safer working environment for everyone involved.

Why Forklift Collision Avoidance

Forklift collision avoidance is crucial in ensuring the safety of both workers and materials in a warehouse or industrial setting. Collisions involving forklifts can result in serious injuries, damage to equipment, and costly downtime. By implementing collision avoidance systems such as sensors, cameras, and alarms, the risk of accidents can be significantly reduced. These systems help alert operators to potential hazards, prevent collisions with other vehicles or obstacles, and ultimately improve overall workplace safety. In summary, forklift collision avoidance is essential for preventing accidents, protecting assets, and promoting a safe working environment.

Recent Technology Development of Forklift Collision Avoidance

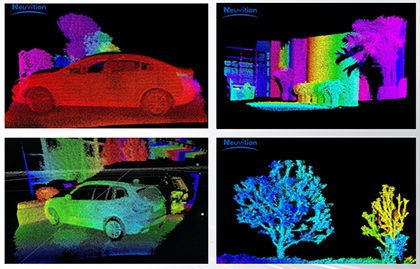

Recent technology developments in forklift collision avoidance have focused on implementing advanced sensors and artificial intelligence algorithms to improve safety in warehouses and industrial settings. These systems utilize cameras, LiDAR, radar, and ultrasonic sensors to detect obstacles and pedestrians in the vicinity of the forklift. By analyzing real-time data and predicting potential collisions, the system can alert the operator or automatically apply brakes to prevent accidents. Additionally, some systems incorporate machine learning algorithms to continuously improve their accuracy and effectiveness in avoiding collisions. Overall, these advancements in forklift collision avoidance technology are crucial for enhancing workplace safety and reducing the risk of accidents in busy warehouse environments. Brief Answer: Recent technology developments in forklift collision avoidance focus on utilizing advanced sensors and artificial intelligence algorithms to enhance safety in warehouses by detecting obstacles and pedestrians, predicting potential collisions, and alerting operators or applying brakes to prevent accidents.

Applications of Forklift Collision Avoidance

Forklift collision avoidance technology is becoming increasingly important in industrial settings to improve safety and efficiency. By utilizing sensors, cameras, and other advanced technologies, forklifts can detect obstacles, pedestrians, and other vehicles in their path, helping to prevent accidents and collisions. This technology not only reduces the risk of injuries and damage to equipment but also enhances productivity by allowing for smoother and more efficient operations. Overall, the applications of forklift collision avoidance systems are crucial in creating a safer work environment and optimizing workflow in warehouses, distribution centers, and manufacturing facilities.

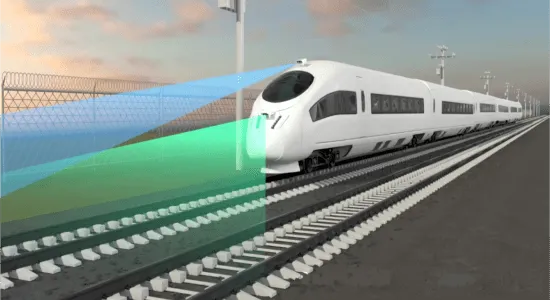

Neuvition Collision Avoidance Systems for Railway

Our collision avoidance systems for railway are designed to enhance safety and prevent accidents on rail tracks. By combining our state-of-the-art LiDAR sensors with advanced software algorithms, we offer the following advantages:

Advantage

- Accurate detection and identification of obstacles in front of trains

- Real-time warning alerts to prevent collisions

- Integration with cameras and other sensors for comprehensive situational awareness

- Customizable solutions to meet specific railway requirements

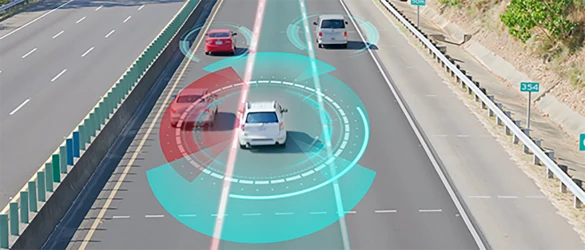

Neuvition Collision Avoidance Systems for Automotive

Our collision avoidance systems for automotive applications are designed to improve road safety and enable autonomous driving capabilities. We offer the following benefits with our integrated LiDAR, Radar, and Camera solutions.

Advantage

- 360-degree detection and tracking of surrounding objects

- Advanced object recognition and classification

- Real-time decision-making for collision avoidance

- Seamless integration with existing vehicle systems

FAQ

Contact Us

If you have any questions or suggestions, please leave a message, we will get in touch with you within 24 hours!