What are Gas Volume Measuring Devices?

Gas volume measuring devices are instruments used to accurately measure the volume of gas in a given space or container. These devices are essential for various industries such as oil and gas, manufacturing, and environmental monitoring. They work by utilizing different methods such as displacement, pressure, or thermal conductivity to determine the volume of gas present. Gas volume measuring devices play a crucial role in ensuring safety, efficiency, and compliance with regulations in different applications where precise gas volume measurements are required. In summary, gas volume measuring devices are tools that provide accurate and reliable measurements of gas volume for a wide range of industrial and scientific purposes.

Why are Gas Volume Measuring Devices Important?

Gas volume measuring devices are important for a variety of reasons. Firstly, they play a crucial role in ensuring accurate measurements of gas quantities, which is essential for various industries such as oil and gas, manufacturing, and environmental monitoring. These devices help in determining the amount of gas being used or produced, which is vital for efficiency and cost-effectiveness. Additionally, gas volume measuring devices are essential for safety purposes, as they help in detecting leaks or abnormal gas flow rates that could pose a risk to workers and the environment. Overall, these devices are indispensable tools for maintaining control over gas usage, ensuring compliance with regulations, and promoting overall safety in industrial operations.

Technologies Used in Gas Volume Measuring Devices

Gas volume measuring devices utilize a variety of technologies to accurately measure and monitor the volume of gas in different applications. Some common technologies used in these devices include ultrasonic sensors, thermal mass flow meters, and differential pressure sensors. Ultrasonic sensors work by emitting sound waves into the gas stream and measuring the time it takes for the waves to bounce back, providing an accurate measurement of the gas volume. Thermal mass flow meters measure the heat transfer between a heated sensor and the gas flow, allowing for precise volume measurements. Differential pressure sensors use the difference in pressure across a restriction in the gas flow to calculate the volume of gas passing through. These technologies play a crucial role in ensuring accurate and reliable gas volume measurements in various industrial processes and applications. Brief answer: Gas volume measuring devices utilize technologies such as ultrasonic sensors, thermal mass flow meters, and differential pressure sensors to accurately measure and monitor the volume of gas in different applications.

Recent Advancements in Gas Volume Measuring Devices

Recent advancements in gas volume measuring devices have revolutionized the way industries and researchers monitor and control gas flow. Traditional methods of measuring gas volume often involved bulky equipment and manual calculations, but with the introduction of advanced technologies such as ultrasonic sensors, laser-based systems, and smart meters, the accuracy and efficiency of gas volume measurement have significantly improved. These modern devices offer real-time data monitoring, remote access capabilities, and enhanced precision, allowing for better decision-making and optimization of gas usage. Overall, these advancements have led to increased productivity, reduced costs, and improved safety in various sectors that rely on accurate gas volume measurements. Brief answer: Recent advancements in gas volume measuring devices have greatly improved accuracy, efficiency, and safety in monitoring and controlling gas flow in industries and research settings.

Application Areas of Gas Volume Measuring Devices

Gas volume measuring devices are essential tools used in various application areas to accurately measure and monitor the volume of gas being produced, consumed, or transported. These devices find wide applications in industries such as oil and gas, chemical processing, power generation, and environmental monitoring. In the oil and gas industry, gas volume measuring devices are used to monitor gas production rates, optimize extraction processes, and ensure compliance with regulatory standards. In chemical processing plants, these devices help in controlling the flow of gases for efficient production processes. In power generation facilities, gas volume measuring devices are crucial for monitoring gas consumption and ensuring the proper functioning of equipment. Additionally, these devices are also used in environmental monitoring to measure gas emissions and air quality levels. Overall, gas volume measuring devices play a vital role in ensuring accurate measurement and control of gas volumes in various industrial applications. Brief Answer: Gas volume measuring devices are utilized in industries such as oil and gas, chemical processing, power generation, and environmental monitoring to accurately measure and monitor gas production, consumption, and transportation, ensuring efficient processes and regulatory compliance.

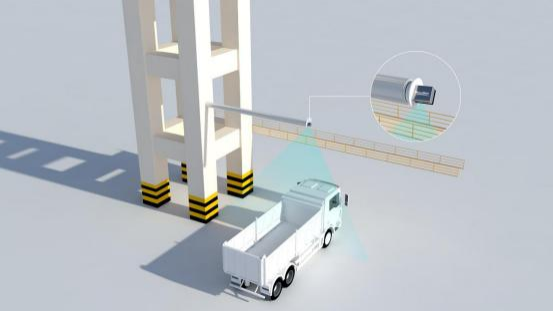

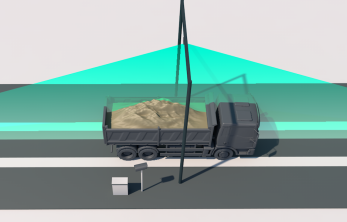

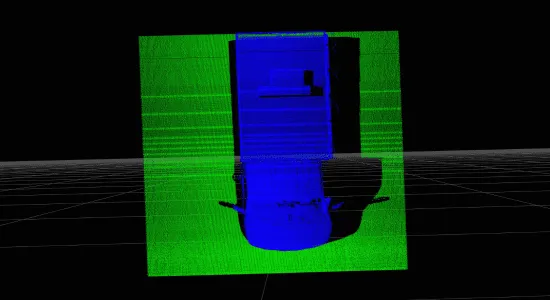

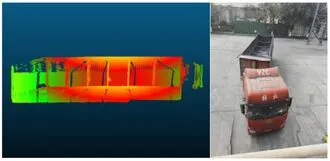

Neuvition Volume Measurement Solution

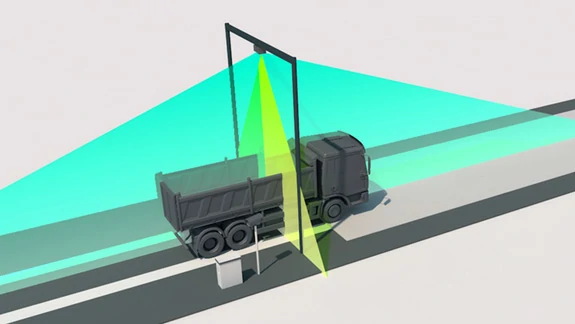

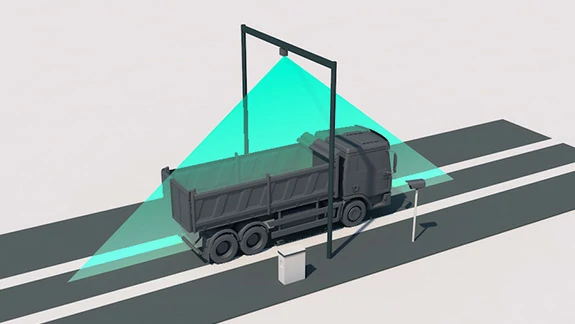

Neuvition offers a comprehensive volume measurement solution designed to meet the needs of various industries, including truck, warehouse, and outdoor pile measurement. Our solutions leverage advanced technologies to provide accurate, reliable, and cost-effective volume measurement data, enabling businesses to optimize their operations and make data-driven decisions.

Neuvition Single Line LiDAR Solutions

Neuvition's Single Line LiDAR solutions, including the Titan M1 SL, Titan P1, and Titan W1 with PTZ, are designed to provide accurate and efficient volume measurement in various applications. These solutions combine high-resolution laser scanning with advanced software to deliver precise data and user-friendly interfaces, making volume measurement more accessible and effective than ever before.

FAQ

Contact Us

If you have any questions or suggestions, please leave a message, we will get in touch with you within 24 hours!