What is SICK LIDAR

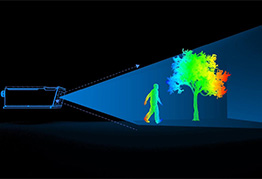

SICK LIDAR, or Light Detection and Ranging, is a technology that uses laser beams to measure distances and create detailed 3D maps of surroundings. It is commonly used in autonomous vehicles, robotics, and industrial automation for navigation and obstacle detection. SICK LIDAR systems are known for their high accuracy, reliability, and ability to operate in various environmental conditions. Overall, SICK LIDAR plays a crucial role in enabling machines to perceive and interact with their surroundings effectively.

The Main Technology in SICK LIDAR

The main technology in SICK LIDAR is the use of Light Detection and Ranging (LIDAR) technology. LIDAR works by emitting laser pulses and measuring the time it takes for the light to bounce back from objects in its path, allowing for highly accurate 3D mapping of the surrounding environment. This technology enables SICK LIDAR sensors to provide precise and reliable data for a wide range of applications, including autonomous vehicles, robotics, and industrial automation. In summary, the main technology in SICK LIDAR is LIDAR technology, which utilizes laser pulses to create detailed 3D maps of the environment for various industries and applications.

Applications of SICK LIDAR

SICK LIDAR, a type of Light Detection and Ranging technology, has a wide range of applications across various industries. One of the key uses of SICK LIDAR is in autonomous vehicles for obstacle detection and navigation. The high-resolution 3D mapping capabilities of SICK LIDAR enable vehicles to accurately perceive their surroundings and make real-time decisions to avoid collisions. Additionally, SICK LIDAR is utilized in industrial automation for tasks such as object detection, positioning, and quality control. Its ability to provide precise measurements and reliable data makes it an essential tool in optimizing manufacturing processes. Overall, the applications of SICK LIDAR are diverse and continue to expand as technology advances. Brief answer: SICK LIDAR is commonly used in autonomous vehicles for obstacle detection and navigation, as well as in industrial automation for tasks like object detection and quality control.

Benefits of SICK LIDAR

Sick lidar technology offers a multitude of benefits across various industries. One key advantage is its high level of accuracy in detecting and measuring objects in its surroundings, making it an essential tool for autonomous vehicles, robotics, and industrial automation. Sick lidar also provides real-time data that can be used for mapping, navigation, and obstacle avoidance, enhancing safety and efficiency in operations. Additionally, its ability to work effectively in various environmental conditions, such as low light or adverse weather, further highlights its reliability and versatility. In conclusion, the benefits of sick lidar technology lie in its precision, real-time data capabilities, and adaptability to different settings, making it a valuable asset for a wide range of applications.

LiDAR in Construction Monitoring

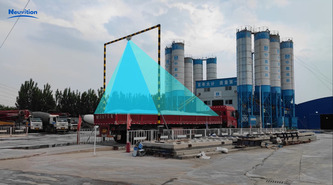

Neuvition's Titan series LiDAR sensors offer high-precision 3D scanning capabilities

ideal for construction site monitoring. The Titan M1 series, with its long-range and

high-resolution features, can capture detailed site data for accurate progress tracking

and volumetric measurements.

Neuvition LiDAR Products Overview

Titan S2

Specialized for specific industrial uses.

NeuX1

Next-generation LiDAR technology with enhanced capabilities.

Titan M1 Series

Long-range, high-resolution LiDAR sensors for various applications.

Titan W1

Designed for wide-angle scanning in challenging environments.

Titan P1

Compact and versatile for mobile and robotics applications.

Neuvition LiDAR Products Overview

Railway Collision Avoidance

Enhancing safety in rail transportation.

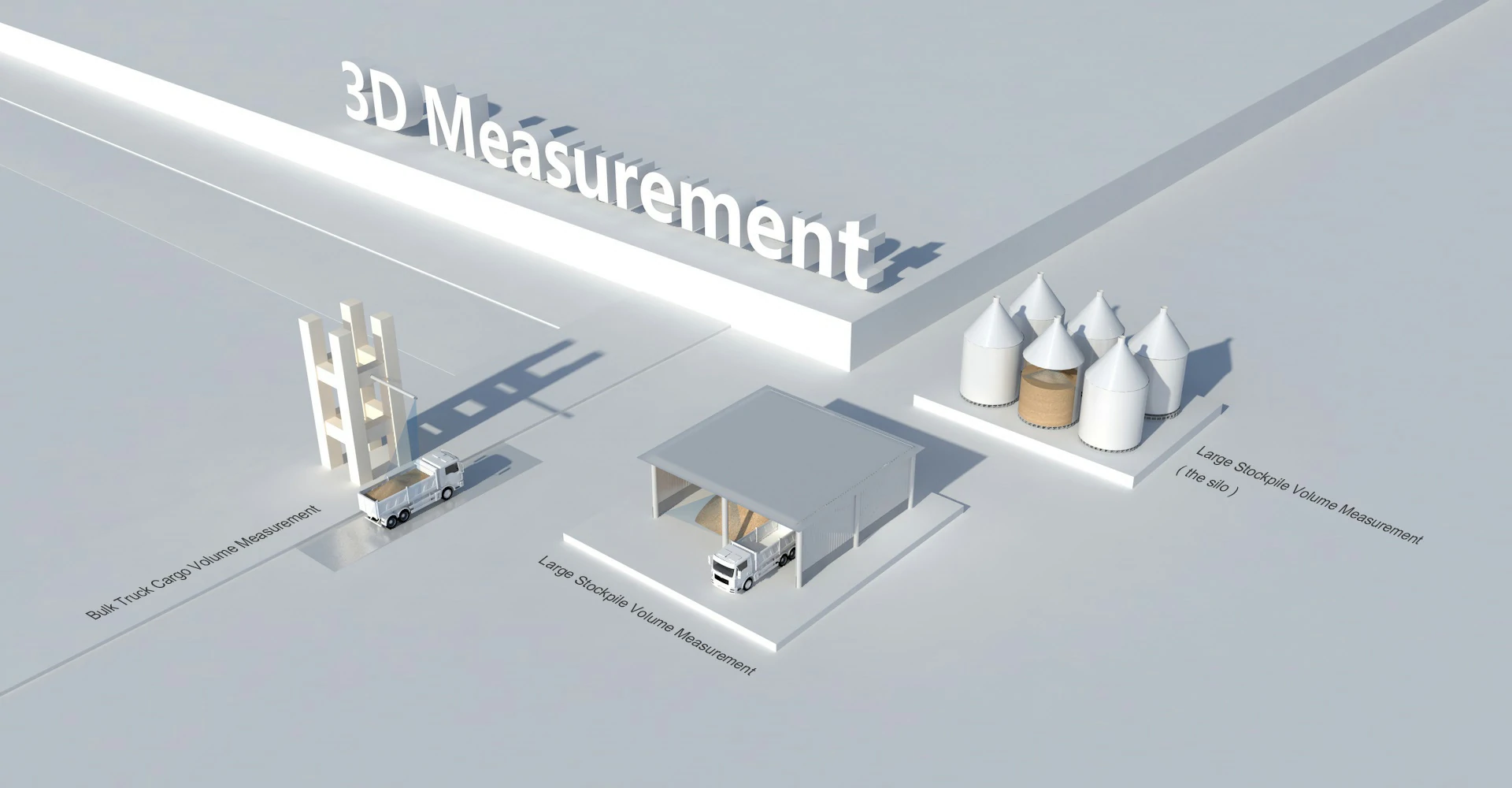

Volume Measurement

Accurate 3D volume calculations for industries like mining and construction.

Smart Highway

Improving road safety and traffic management.

Robotics

Enabling precise navigation and object detection for autonomous robots.

Autonomous Driving

Advanced sensing for self-driving vehicles.

Application Areas of LiDAR

Benefits of Using LiDAR

High accuracy and

precision in 3D mapping

Real-time data

collection and processing

Ability to penetrate vegetation

and capture ground topography

Efficient large-scale

surveying and mapping

Enhanced safety in

autonomous systems

Improved decision-making

with detailed spatial information

Software Solutions for LiDAR

Neuvition provides software solutions to complement its hardware, including point cloud processing and analysis

tools, real-time visualization software, a data integration platform for enterprise applications, and customized

algorithms tailored to specific industry needs.

Success Stories

MetroInnovate Urban Solutions improved traffic flow by 15% after implementing Neuvition's Smart Highway system. Emily Parker, the Director of Smart City Development, played a key role in deploying this system to enhance urban traffic management and reduce congestion.

BuildMaster Construction reduced project timelines by 20% using Neuvition's LiDAR-based site monitoring solution. Michael Thompson, the COO, led the adoption of this technology, focusing on improving efficiency and project management.

DeepCore Mining increased excavation efficiency by 25% with Neuvition's volume measurement solution. Robert Lin, the Head of Operations, was instrumental in integrating this technology to optimize resource extraction and operational productivity.

FAQ

Contact Us

If you have any questions or suggestions, please leave a message, we will get in touch with you within 24 hours!