What are How To Measure Epoxy By Volume?

Measuring epoxy by volume is a crucial step in ensuring the proper ratio of resin to hardener for successful curing and optimal performance of the epoxy. To measure epoxy by volume, you will need to use measuring cups or graduated containers that are specifically designed for liquids. Start by pouring the required amount of resin into the container, making sure to fill it to the desired volume mark. Then, add the corresponding amount of hardener to achieve the correct ratio. It is important to follow the manufacturer's instructions carefully to ensure accurate measurements and a strong, durable bond. By measuring epoxy by volume, you can achieve consistent results and avoid issues such as under-curing or over-curing.

Why are How To Measure Epoxy By Volume Important?

Understanding how to measure epoxy by volume is important because it ensures the proper ratio of resin to hardener is maintained, which is crucial for the epoxy to cure and bond effectively. Measuring epoxy by volume allows for accurate mixing, resulting in a strong and durable final product. This precision is essential in various applications such as crafting, woodworking, and construction, where the quality and integrity of the epoxy bond are paramount. By following proper measurement techniques, users can achieve consistent results and avoid issues such as incomplete curing or weak bonds.

Technologies Used in How To Measure Epoxy By Volume

In the process of measuring epoxy by volume, various technologies are utilized to ensure accuracy and efficiency. One common technology used is a digital scale, which allows for precise measurements of the epoxy resin and hardener components. Additionally, graduated cylinders or beakers are often employed to accurately measure the volume of each component before mixing them together. Some advanced techniques may involve the use of automated dispensing systems or software programs that calculate the correct ratios based on the desired outcome. Overall, these technologies play a crucial role in ensuring the proper measurement and mixing of epoxy components for successful applications. Brief answer: Technologies such as digital scales, graduated cylinders, and automated dispensing systems are commonly used in measuring epoxy by volume to ensure accuracy and efficiency in the mixing process.

Recent Advancements in How To Measure Epoxy By Volume

Recent advancements in how to measure epoxy by volume have revolutionized the way epoxy products are used in various industries. Traditional methods of measuring epoxy by volume often involved using graduated cylinders or other manual tools, which could lead to inaccuracies and inconsistencies in the final product. However, with the introduction of digital scales and automated dispensing systems, measuring epoxy by volume has become more precise and efficient. These new technologies allow for greater control over the mixing process, resulting in higher quality end products. Overall, these advancements have significantly improved the accuracy and reliability of measuring epoxy by volume, making it easier for manufacturers and users to achieve consistent results.

Application Areas of How To Measure Epoxy By Volume

The application areas of "How To Measure Epoxy By Volume" are vast and diverse, ranging from industrial settings to DIY projects. In industries such as construction, automotive, aerospace, and marine, accurate measurement of epoxy by volume is crucial for ensuring the proper mixing ratio and achieving desired properties in the final product. Additionally, in art and crafting, measuring epoxy by volume is essential for creating resin art pieces, jewelry, and other creative projects. Overall, understanding how to measure epoxy by volume is fundamental in various fields to achieve optimal results and ensure the success of projects. Brief answer: The application areas of "How To Measure Epoxy By Volume" include industries such as construction, automotive, aerospace, and marine, as well as art and crafting projects where accurate measurement is essential for achieving desired results.

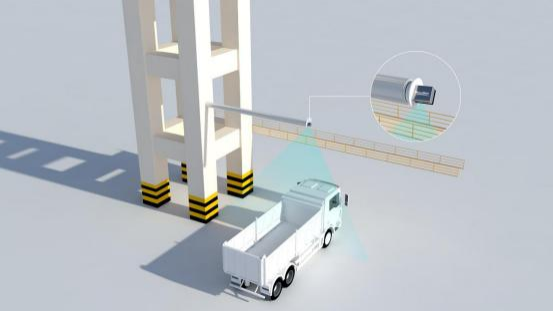

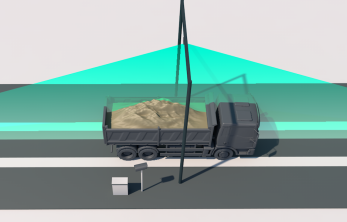

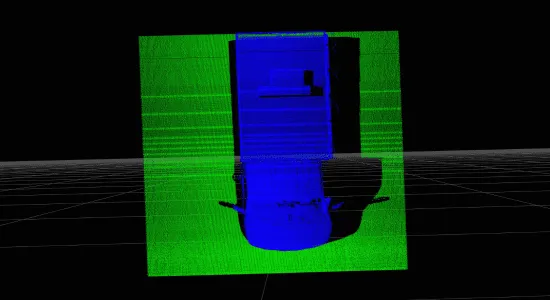

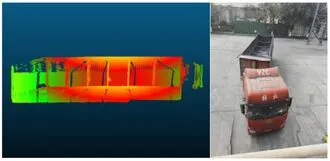

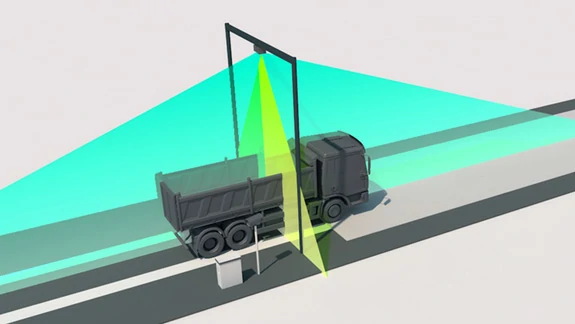

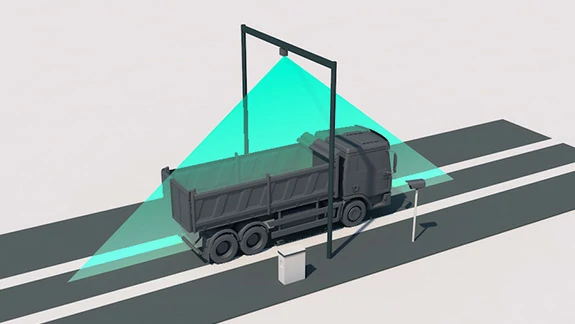

Neuvition Volume Measurement Solution

Neuvition offers a comprehensive volume measurement solution designed to meet the needs of various industries, including truck, warehouse, and outdoor pile measurement. Our solutions leverage advanced technologies to provide accurate, reliable, and cost-effective volume measurement data, enabling businesses to optimize their operations and make data-driven decisions.

Neuvition Single Line LiDAR Solutions

Neuvition's Single Line LiDAR solutions, including the Titan M1 SL, Titan P1, and Titan W1 with PTZ, are designed to provide accurate and efficient volume measurement in various applications. These solutions combine high-resolution laser scanning with advanced software to deliver precise data and user-friendly interfaces, making volume measurement more accessible and effective than ever before.

FAQ

Contact Us

If you have any questions or suggestions, please leave a message, we will get in touch with you within 24 hours!

Arabic

Arabic Chinese (Simplified)

Chinese (Simplified) Chinese (Traditional)

Chinese (Traditional) Dutch

Dutch English

English Filipino

Filipino Finnish

Finnish French

French German

German Hebrew

Hebrew Hindi

Hindi Italian

Italian Japanese

Japanese Korean

Korean Portuguese

Portuguese Russian

Russian Spanish

Spanish Swedish

Swedish Thai

Thai Turkish

Turkish Vietnamese

Vietnamese