Truck Volume Measurement Customer Use Case -Renovation of Automatic Loading System for Cement Plant

Author: Release time:2024-01-12 09:01:04

In the cement manufacturing industry, efficient loading and unloading operations are crucial for ensuring smooth production and timely delivery of products. However, many cement plants still rely on manual labor for these tasks, which can lead to various problems such as material overflow and unnecessary labor waste. To address these issues, Neuvition has developed a static truck volume measurement system that utilizes advanced technologies like LiDAR and license plate recognition to achieve accurate truck volume measurement and automated loading processes.

Project Background

The customer is a cement manufacturer that ships thousands of tons of cement and clinker products daily. Currently, the loading operation still relies on experienced employees to manually operate it. As shown in the figure:

Problems Faced by the Customer:

1. Due to manual operation during unloading, materials often overflow due to staff negligence.

2. During the off-peak season, although the shipment volume is low, a worker still needs to be assigned to be on duty, resulting in unnecessary labor waste.

3. During the peak season, 24-hour loading is often required, and 2-3 workers need to be arranged to take turns on duty, making it difficult to manage due to inconsistent personnel.

System Solution

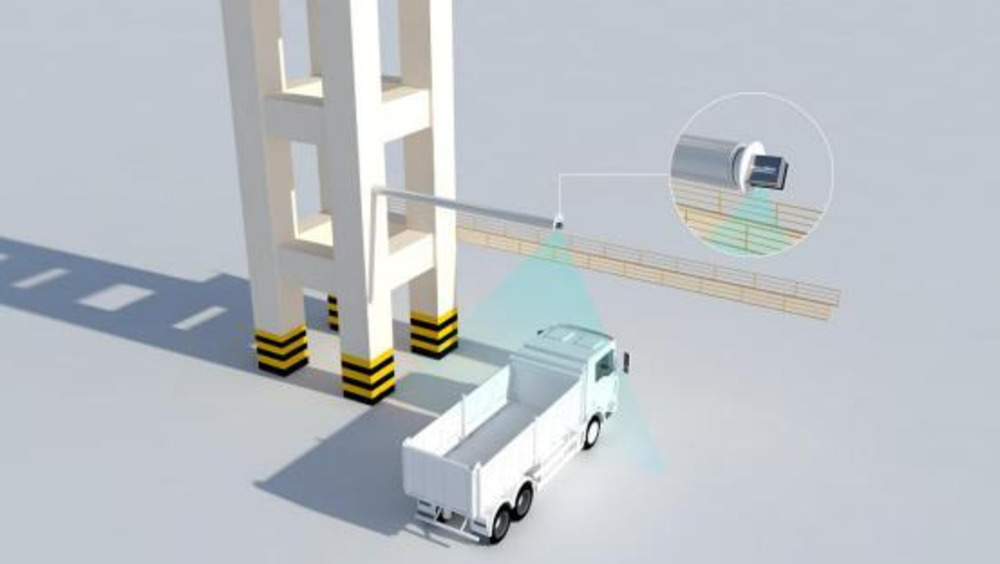

To overcome these challenges and improve the efficiency of the loading process at the cement plant, Neuvition proposed a static truck volume measurement system based on truck license plate recognition technology. This innovative solution combines LiDAR technology with license plate recognition systems and cameras to achieve high-precision measurement of truck volumes. Additionally, an encoder is used for accurate positioning of the unloading outlet during the loading process.

Principle of Solution:

The Neuvition static truck volume measurement system is built upon their independently developed LiDAR technology integrated with rotating PTZ.

1. When a truck enters the measurement area at the plant site, the recognition system records its license plate information.

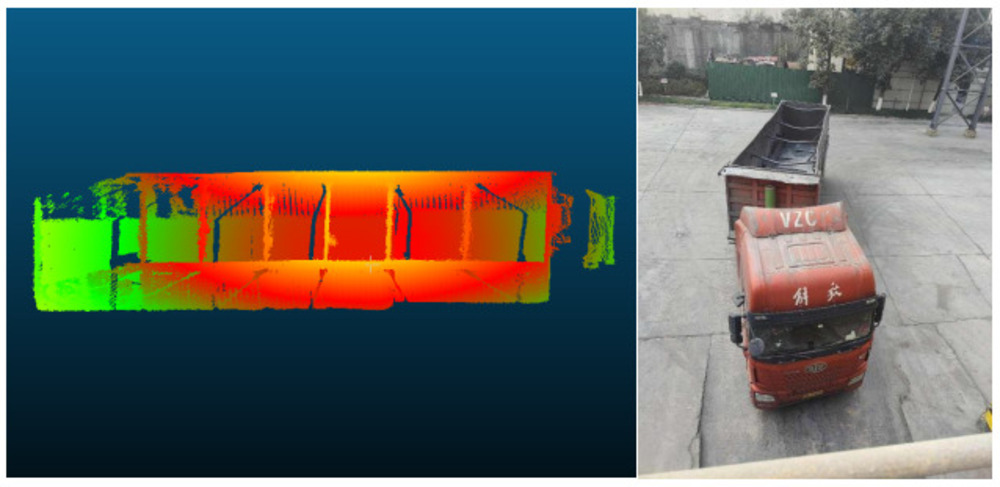

2. The measurement system then scans the truck using LiDAR technology and calculates its length, width, height, and volume through an AI algorithm.

3. The unloading system uses the truck information and measurement results to calculate the material output automatically and waits for the truck to enter the loading area before starting automatic loading.

System Improvement:

To address specific challenges faced by the customer, Neuvition made certain improvements to their system:

1. Vehicle cover recognition: As vehicles on-site vary in size and some have canvas covers, Neuvition added a feature to recognize vehicle covers. If a driver forgets to put down the cover, the system prompts them to ensure proper loading.

2. Customizable weight settings: Some vehicles may need long-distance transportation on highways, and overloading can lead to material scattering during high-speed driving, posing safety risks. To mitigate this issue, Neuvition added an operational function interface that allows drivers to set the weight of materials loaded according to their specific requirements.

Project Achievements:

The implementation of Neuvition’s static truck volume measurement system has brought significant benefits for the cement plant customer:

1. Unattended operation: The automated system eliminates the need for a worker on duty during loading operations, allowing truck drivers to complete loading tasks independently without strict time limits.

2. Traceable information: Through a backend platform provided by Neuvition’s system, customers can now access past shipment information easily. This traceable data helps with production material management and enables more scientific production planning.

3. Intelligent solution: By leveraging advanced technologies like LiDAR and license plate recognition combined with background algorithms, accurate measurement of truck volumes is achieved consistently. This intelligent solution adds value by improving efficiency and reducing errors in the loading process.

Conclusion

The renovation of an automatic loading system using Neuvition’s static truck volume measurement technology has proven beneficial for a cement plant customer facing various challenges related to manual labor-dependent operations. By implementing this innovative solution based on LiDAR technology and license plate recognition systems, significant improvements in efficiency, safety, and traceability have been achieved. The success of this project highlights the value of intelligent solutions in optimizing industrial processes and enhancing overall productivity.