Exploring the Impact of LiDAR Technology on Port Automation

Author: Release time:2023-08-28 09:51:37

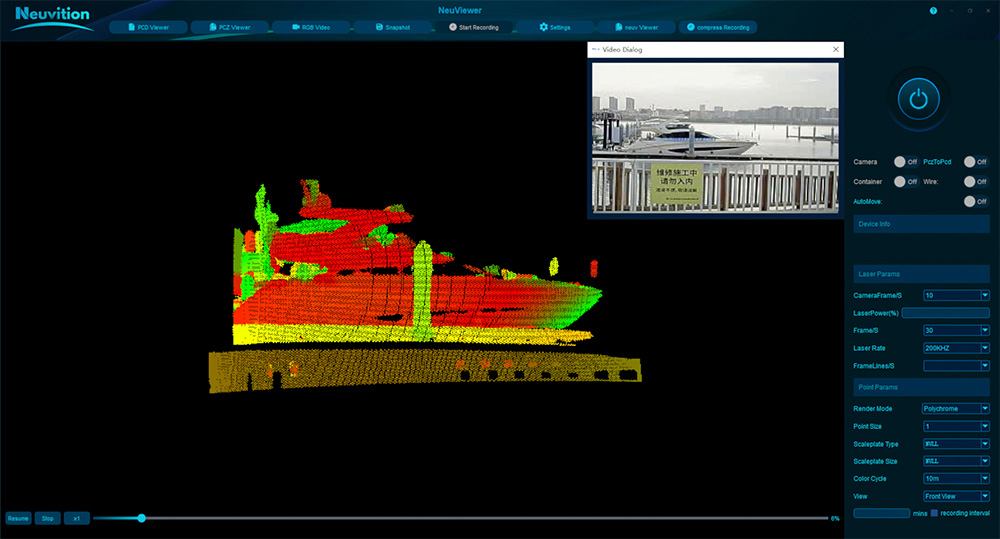

With the development of automated technology in recent years, the shipping industry has undergone tremendous change. These improvements have transformed port operations, making them more efficient, cost-effective, and environmentally conscious. LiDAR (Light Detection and Ranging) is one such technology that has gained significance in port automation. LiDAR technology employs laser beams to detect distances and build comprehensive 3D maps of its surroundings. This blog will take a look at the impact of LiDAR technology on port automation and how it will influence the future of marine logistics.

Increased Safety Measures:

Safety is a primary issue in any industrial setting, particularly in ports where heavy machinery is used alongside workers. Traditional safety precautions frequently rely solely on human alertness, which is prone to errors or oversight. However, by incorporating LiDAR technology into port automation, safety precautions are dramatically enhanced.

LiDAR sensors can identify things in real time and offer precise measurements of the distance from nearby equipment or personnel. This allows autonomous systems to make informed decisions about collision avoidance or emergency braking when necessary. LiDAR contributes to a safer working environment for workers and machines by minimizing human error and enhancing situational awareness.

Highly Effective Container Handling:

One of the most crucial areas of port operations that directly affects efficiency and productivity levels is container handling. Traditionally, this kind of task needed physical labor to load and unload containers from ships onto trucks or freight trains for inland transportation.

These operations can now be automated with better precision and speed using LiDAR technology incorporated with container handling equipment such as cranes or straddle carriers. LiDAR sensors’ 3D mapping capabilities enable machines to accurately determine container placements while avoiding hindering factors during transportation.

Automated container handling not only decreases labor expenses but also reduces human error associated with manual work, such as container misplacement or damage during handling processes.

Better Traffic Management:

Ports are bustling centers of activity, with a steady flow of vehicles and equipment. Efficient traffic management is critical for avoiding congestion, delays, and accidents, which may interrupt port automation.

The use of LiDAR technology is critical to optimizing traffic flow within ports. LiDAR sensors enable automated systems to make intelligent route planning and vehicle coordination decisions by delivering real-time data on vehicle placements and movements. This promotes efficient traffic movement while reducing the possibility of crashes or bottlenecks.

Furthermore, LiDAR sensors may detect unauthorized vehicles or persons entering restricted areas, sending immediate alerts to security personnel so that appropriate action can be taken. This improves overall security at the port automation.

Environmental Benefits:

Because of worries about carbon emissions and pollution, the shipping sector has been under growing pressure to lessen its environmental impact. LiDAR technology contributes tremendously to accomplishing these sustainability goals by enabling more efficient resource use.

LiDAR decreases fuel consumption associated with traditional manual operations by optimizing container handling processes via automation. Using LiDAR sensors, automated systems can compute the most energy-efficient routes for moving vehicles within the port grounds, reducing unnecessary travel miles.

Furthermore, LiDAR technology assists in finding possible energy-saving options, such as adjusting lighting systems based on real-time occupancy data or detecting pipeline leaks for quick repairs.

Future Prospects:

While existing applications of LiDAR technology in port automation have already transformed maritime logistics, there are a number of interesting potential developments to look forward to:

a) Autonomous Vessels: Integrating LiDAR sensors into autonomous vessels could allow them to sail through crowded ports securely without the need for human intervention. This would significantly simplify shipping operations while lowering the personnel expenses associated with crewed vessels.

b) Predictive Maintenance: Predictive maintenance models can be constructed by continuously monitoring equipment using LiDAR sensors’ precise measurements and 3D mapping capabilities. These models would aid in the identification of potential defects or failures prior to their occurrence, allowing for preventative maintenance procedures that would reduce downtime and boost operational efficiency.

c) Port Expansion Planning: LiDAR technology can help with precise mapping and surveying of port areas, assisting in the planning and design of future expansions. This ensures that available space is utilized optimally while taking environmental conditions and possible infrastructure requirements into account.

Conclusion:

LiDAR technology has emerged as a game changer in port automation, transforming maritime logistics by boosting safety measures, improving container handling efficiency, optimizing traffic management, and minimizing the negative environmental impact. The integration of LiDAR sensors into automated systems has paved the way for higher productivity, cost savings, and sustainability in the shipping industry.