How Crucial Is LiDAR For Tunnel Detection?

Author: Release time:2023-02-27 08:46:35

The importance of tunnel detection: tunnel detection is a crucial and challenging task. In addition to ensuring the safety of tunnel construction and operation, tunnel detection can check whether environmental factors like temperature, humidity, and wind speed inside the tunnel can meet safety standards.

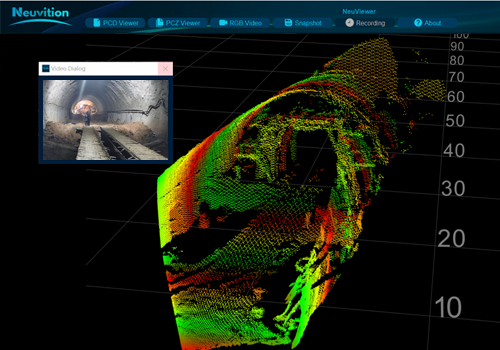

Here is the customer test case of Neuvition LiDAR for mine tunnel foreign object detection. Please watch the point cloud effect:

Commonly-used equipment and technologies for tunnel detection

Tunnel detection equipment mainly includes electric chromatograph, non-destructive ultrasonic tester, wall penetration instrument, gamma camera, laser scanner, flaw detector, etc. The detection technologies mainly include radiographic imaging technology, laser scanning technology, ultrasonic detection technology, magnetic powder flaw detection technology, electron tomography technique, etc.

Radiation imaging technology mainly uses intense radioactive X-rays to irradiate the tunnel, inspect the structural defects of the tunnel from the inside, and detect the internal element composition of the cave wall.

Laser scanning technology mainly uses laser scanners to detect possible cracks, hollowing, unevenness, dirt, leakage, etc. on the tunnel wall.

Ultrasonic testing technology uses the principle of ultrasonic reflection to detect structural defects and holes in tunnels.

Application of LiDAR in tunnel detection

1. It is based on LiDAR and utilizes three-dimensional laser scanning measurement and data visualization processing technology to obtain real-time, accurate, and all-encompassing tunnel spatial deformation data, perform tunnel deformation analysis and execute warning and alarm for tunnel construction;

2. To ensure the safety of vehicles and personnel, LiDAR is used to monitor the behavior of tunnel rail trains as well as to detect and provide early warning of foreign object intrusion on and around the track;

Benefits of using LiDAR for tunnel detection

LiDAR scanning systems can perform with some level of automation. It is capable of scanning the tunnel in three dimensions, as well as constructing a three-dimensional spatial image in real time. LiDAR can effectively provide the tunnel safety index, when used in tunnel detection. This detection method not only avoids the drawbacks of conventional detection methods, but also automates the process to increase safety and efficiency.

Challenges of LiDAR in tunnel detection applications

1. Signal interference: The air humidity in the tunnel is high, and countless external signals are reflected from the tunnel boundary, which will affect the accuracy of the LiDAR;

2. Environmental variables: LiDAR needs to resist temperature changes and humidity changes in the tunnel, as well as possible dust and other pollutants. These variables may have some impact on the performance of LiDAR;

3. LiDAR installation and debugging: LiDAR needs to be installed in a designated location, and needs to be accurately debugged according to the environment, to ensure that it can capture and analyze signals in the tunnel well;

4. LiDAR maintenance: LiDAR needs regular inspection and maintenance, to prevent dust and pollutants from blocking the window.